New Products

Find Medical&Healthcare PCBA, Circuit Board Assembly , Circuit Board Manufacturing on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

Model No.: BM-010

Welcome To Moko

One stop Electronic manufacturing service

Moko, your single point of contact for all of your raw materials, parts, and PCB assembly, also offers:

- Contract Manufacturing

- Engineering Services

- PCB Design & Assembly

- Product Design

- Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

Electronics Printed Circuit Board Manufacture

ROHS Approved Assembled Pcb Board

Multy Layer PCB PCBA

PCB Technical Specification

layer | 1-18 layer |

Material | FR-4,CEM-1,CEM-3,High TG,FR4 Halogen Free,FR-1,FR-2 |

Board thickness | 0.2mm-4mm |

Max.finished board side | 800*508mm |

Min.drilled hole size | 0.25mm |

min.line width | 0.075mm(3mil) |

min.line spacing | 0.075mm(3mil) |

Surface finish/treatment | HALS/HALS lead free,Chemical tin,Chemical Gold, Immersion gold Immersion Silver/Gold,Osp,Gold Plating |

Copper thickness | 0.5-4.0oz |

Solder mask color | green/black/white/red/blue/yellow |

Inner packing | Vacuum packing,Plastic bag |

Outer packing | standard carton packing |

Hole tolerance | PTH:±0.076,NTPH:±0.05 |

Certificate | UL,ISO9001,ISO14001,ROHS,CQC |

profiling punching | Routing,V-CUT,Beveling |

PCBA Capabilities

Quantity | Prototype&Low Volume PCB Assembly,from 1 Board to 250,is specialty,or up to 1000 |

Type of Assembly | SMT,Thru-hole |

Solder Type | Water Soluble Solder Paste,Leaded and Lead-Free |

Components | Passive Down to 0201 size BGA and VFBGA Leadless Chip Carriers/CSP Double-sided SMT Assembly Fine Pitch to 0.8mils BGA Repair and Reball Part Removal and Replacement |

Bare Board Size | Smallest:0.25*0.25 inches Largest:20*20 inches |

File Formate | Bill of Materials Gerber files Pick-N-Place file |

Types of Service | Turn-key,partial turn-key or consignment |

Component Packaging | Cut Tape,Tube,Reels,Loose Parts |

Turn Time | Same day service to 15 days service |

Testing | Flying Probe Test,X-ray Inspection AOI Test |

PCB Assembly Process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

Quote requirement:

· Gerber file of the bare PCB board

· BOM (Bill of material) for assembly

· To short the lead time, please kindly advise us if there is any acceptable components substitution.

· Testing Guide & Test Fixtures if necessary

· Programming files & Programming tool if necessary

· Schematic if necessary

OEM/ODM/EMS Services for PCBA:

· PCBA, PCB assembly: SMT & PTH & BGA

· PCBA and enclosure design

· Components sourcing and purchasing

· Quick prototyping

· Plastic injection molding

· Metal sheet stamping

· Final assembly

· Test: AOI, In-Circuit Test (ICT), Functional Test (FCT)

· Custom clearance for material importing and product exporting

Orientronic PCB assembly Equipment:

· SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4

· Reflow Oven: FolunGwin FL-RX860

· Wave Soldering Machine: FolunGwin ADS300

· Automated Optical Inspection (AOI): Aleader ALD-H-350B

· Fully Automatic SMT Stencil Printer: FolunGwin Win-5

Q: What files do you use in PCBA fabrication?

A: Gerber or Eagle, BOM listing, PNP and Components Position

Q:Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test procedure?

A: Within 6 hours for PCB quotation and around 24 hours for PCBA quotation.

Q: How can I know the process of my PCBA production?

A: 7-10 days for PCB production and components purchasing, and 10 days for PCB assembly and Testing

Q: How can I make sure the quality of my PCBAs?

A: We ensure that each piece of PCBA products work well before shipping. We'll test all of them according to your test procedure. Also if there are any defect items during the shipping, we also can be free to repair for you.

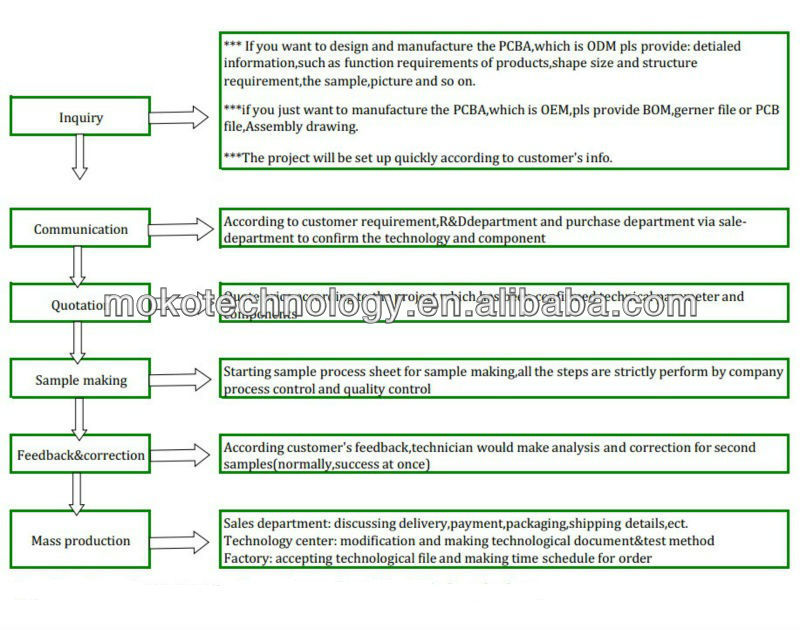

Order Process

1) PCB production time: sample: 4days / mass production: within 15 days

PCB Assembly: samples: within 7 days / mass production: within 15 days

2) Fast PCB delivery: 42 hours ; 72 hours ;

3) Component purchase: 5 days. (3days if all components is available in our domestic market).

Inner packing :Vacuum Package Outer packing:Standard Carton

Shipping Method and Payment terms:

1. By DHL, UPS, FedEx, TNT using clients account.

2. We suggest you using our DHL, UPS, FedEx, TNT forwarder.

3. By EMS (Usually for Russia Clients), price is high.

4. By sea for mass quantity according to customer's requirement.

5. By customer's Forwarder

6.By Paypal,T/T,West Union,etc.

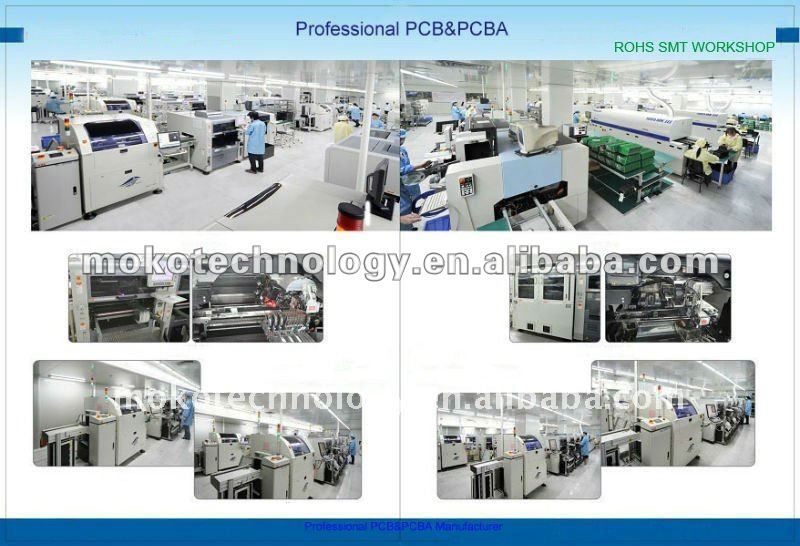

View of MOKO Factory

1)ROHS SMT WORKSHOP

2)High Standard Through-Hole Slodring Workshop

3)Good After Testing Service

Contact us if you need more details on Electronic Board of Medical. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Medical Pcb Pcba Board Assembly、Electronic Medical Pcb Pcba Board. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Medical&Healthcare PCBA